Exploring the World of China CNC Machining Turning Parts Manufacturers

In the evolving landscape of manufacturing, China CNC machining turning parts manufacturers have emerged as key players. These manufacturers are not only pivotal in the realm of metal fabrication but are also redefining standards in precision engineering across the globe. This article delves deep into the factors making these manufacturers essential partners for businesses seeking high-quality, cost-effective solutions.

The Importance of CNC Machining in Modern Manufacturing

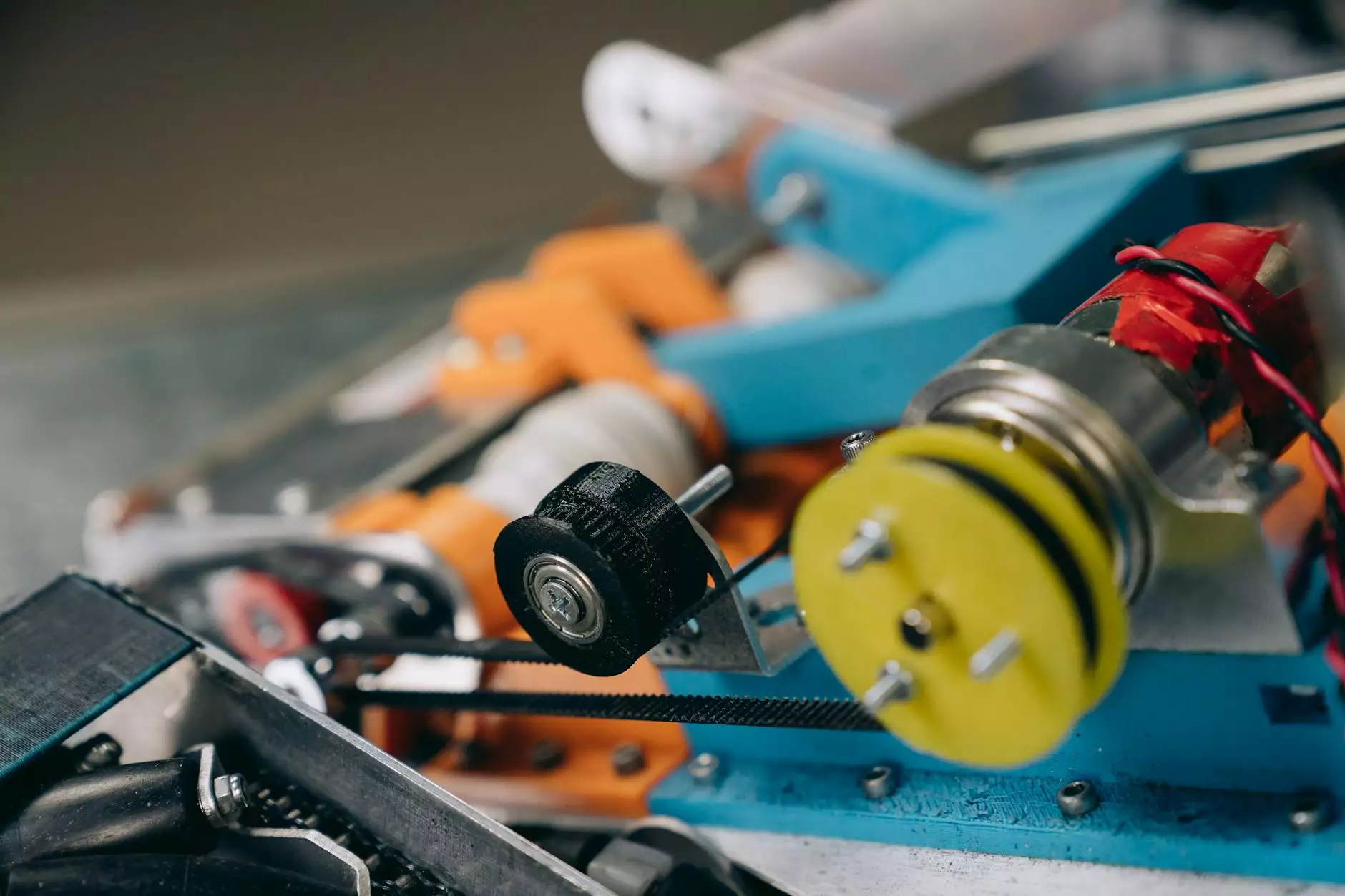

CNC (Computer Numerical Control) machining is a process that allows for the precise and efficient manufacturing of parts. CNC machines are programmed to produce components with extreme accuracy, which is crucial in industries that demand stringent specifications.

CNC machining encompasses various processes, among which turning is particularly significant. Turning works by rotating the workpiece while a cutting tool removes material, enabling the production of cylindrical parts with incredible precision.

Advantages of CNC Machining Turning Parts

- Precision and Accuracy: CNC turning guarantees that each part manufactured meets tight tolerances, reducing errors and enhancing the overall quality.

- Efficiency: With advanced machinery, manufacturers can produce large quantities of parts with minimal downtime.

- Material Versatility: Manufacturers can work with various materials, including metals, plastics, and composites, providing flexibility for different projects.

- Cost-Effectiveness: Even though the initial investment in CNC machinery can be high, the long-term savings through reduced waste and increased production speed are substantial.

Key Players in China CNC Machining Turning Parts Manufacturing

China has positioned itself as a dominant force in the global manufacturing sector, particularly in CNC machining. The country boasts an array of manufacturers specializing in turning parts. Understanding the landscape of these manufacturers is crucial for businesses seeking reliable partners.

Top Characteristics of Leading Manufacturers

When evaluating China CNC machining turning parts manufacturers, it's essential to consider the following characteristics:

- Quality Assurance: Leading manufacturers implement robust quality control measures, ensuring that each part meets international standards.

- Innovative Technology: The best manufacturers invest in state-of-the-art machinery and software to optimize production processes.

- Custom Solutions: They offer tailored manufacturing solutions based on specific customer requirements, which includes custom sizes, materials, and designs.

- Responsive Customer Service: Effective communication and support are vital to handle inquiries and concerns promptly.

The Future of CNC Machining in China

The future of the CNC machining industry in China looks promising, driven by technological advancements and increasing demand from various sectors such as aerospace, automotive, and healthcare. As these industries evolve, the need for high-quality machined parts continues to grow.

Trends Influencing the Industry

- Automation and Robotics: Increased automation in CNC machining processes is expected to enhance precision and reduce production times.

- Smart Manufacturing: The integration of IoT (Internet of Things) in manufacturing processes will allow for real-time monitoring and data analysis, leading to improved efficiency.

- Sustainability: There is a burgeoning focus on sustainable practices and materials in manufacturing, driving companies to adopt eco-friendly methods.

- Skilled Workforce Development: As technology evolves, there is a crucial need for a skilled workforce trained in advanced manufacturing processes.

Choosing the Right Manufacturer

Selecting the appropriate manufacturer for CNC machining turning parts is vital for achieving your project's goals. Here are some steps to consider:

1. Define Your Needs

Outline the specifications of the parts you require, including dimensions, materials, tolerances, and quantities. A clear definition will assist you in communicating effectively with potential manufacturers.

2. Research Potential Manufacturers

Look for manufacturers with a strong reputation in the industry. Consider reviewing their portfolios, client testimonials, and case studies to gauge their expertise.

3. Evaluate Capabilities

Assess the manufacturing capabilities of each company. Ensure they possess the necessary equipment, technology, and knowledge to fulfill your requirements.

4. Quality Certifications

Verify if the manufacturer has relevant quality certifications, such as ISO 9001, which indicates a commitment to quality management systems.

5. Communication and Support

Effective communication is critical. Choose a manufacturer who is responsive and provides clear answers to your inquiries.

Working with DeepMould.net

At DeepMould.net, we pride ourselves on being among the leading China CNC machining turning parts manufacturers. Our commitment to quality, customer satisfaction, and innovative solutions sets us apart in the competitive landscape of metal fabrication.

Our Services Include:

- CNC Turning: Utilizing precision CNC machines, we produce intricate turning parts that meet the highest standards.

- Prototype Development: We assist in developing prototypes to ensure optimal designs before mass production.

- Customized Solutions: Tailored manufacturing capabilities allow us to meet unique project requirements effectively.

- Comprehensive Support: Our dedicated support team guides you through the manufacturing process, ensuring clear communication and timely updates.

Conclusion

As the demand for precision-engineered parts continues to grow, China CNC machining turning parts manufacturers are well-equipped to meet the challenges of modern manufacturing. With advancements in technology and a focus on quality, these manufacturers are poised for growth and innovation.

For businesses looking for reliable, high-quality, and cost-effective machining solutions, engaging with experienced manufacturers like DeepMould.net can result in successful partnerships and outstanding outcomes.

Get in Touch!

If you're interested in learning more about our services or how we can assist with your next project, please contact us today!