Transforming Industries: The Role of an Injection Moulding Manufacturer

Injection moulding manufacturers play a pivotal role in the modern manufacturing landscape, providing essential services that meet the diverse needs of various sectors. At DeepMould.net, we are committed to delivering exceptional injection moulding solutions that cater to both small and large-scale production requirements. Our expertise not only ensures high-quality outputs but also drives innovation in product design and efficiency in manufacturing processes.

The Importance of Injection Moulding in Modern Manufacturing

Injection moulding is not just a manufacturing process; it is a crucial technology that underpins the production of countless everyday items. From automotive components to household appliances, the applications of injection moulding are virtually limitless. Understanding why this process is fundamental to manufacturing involves examining the following key benefits:

- Efficiency: Injection moulding allows manufacturers to produce parts in large quantities with minimal waste. The process is highly automated, ensuring consistent quality and faster turnaround times.

- Complex Shapes: The technique enables the creation of intricate designs that would be impossible or cost-prohibitive with other manufacturing methods.

- Material Versatility: With the ability to use various thermoplastics and thermosetting polymers, injection moulding provides flexibility in material selection to suit specific application needs.

- Cost-Effectiveness: Although the initial setup costs can be high, the long-term savings in production costs and material efficiency make injection moulding a cost-effective option for manufacturers.

DeepMould.net: Your Trusted Injection Moulding Manufacturer

At DeepMould.net, we pride ourselves on being among the leading injection moulding manufacturers. Our extensive experience and commitment to quality have made us a trusted partner for businesses across various industries. Here are some of the reasons why clients choose us:

1. State-of-the-art Technology

We utilize the latest machinery and technology in injection moulding, which allows us to achieve precision and speed in production. Our equipment includes advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) systems designed to streamline the entire manufacturing process.

2. Skilled Workforce

Our team consists of highly trained professionals who possess a deep understanding of the injection moulding process. From design engineers to production specialists, each member of our workforce is committed to ensuring that we meet and exceed our clients' expectations.

3. Custom Solutions

Every project we undertake starts with a comprehensive consultation to understand the unique requirements of our clients. Whether you need prototypes or mass production of complex parts, our team is adept at creating tailored solutions that meet your specifications.

4. Quality Assurance

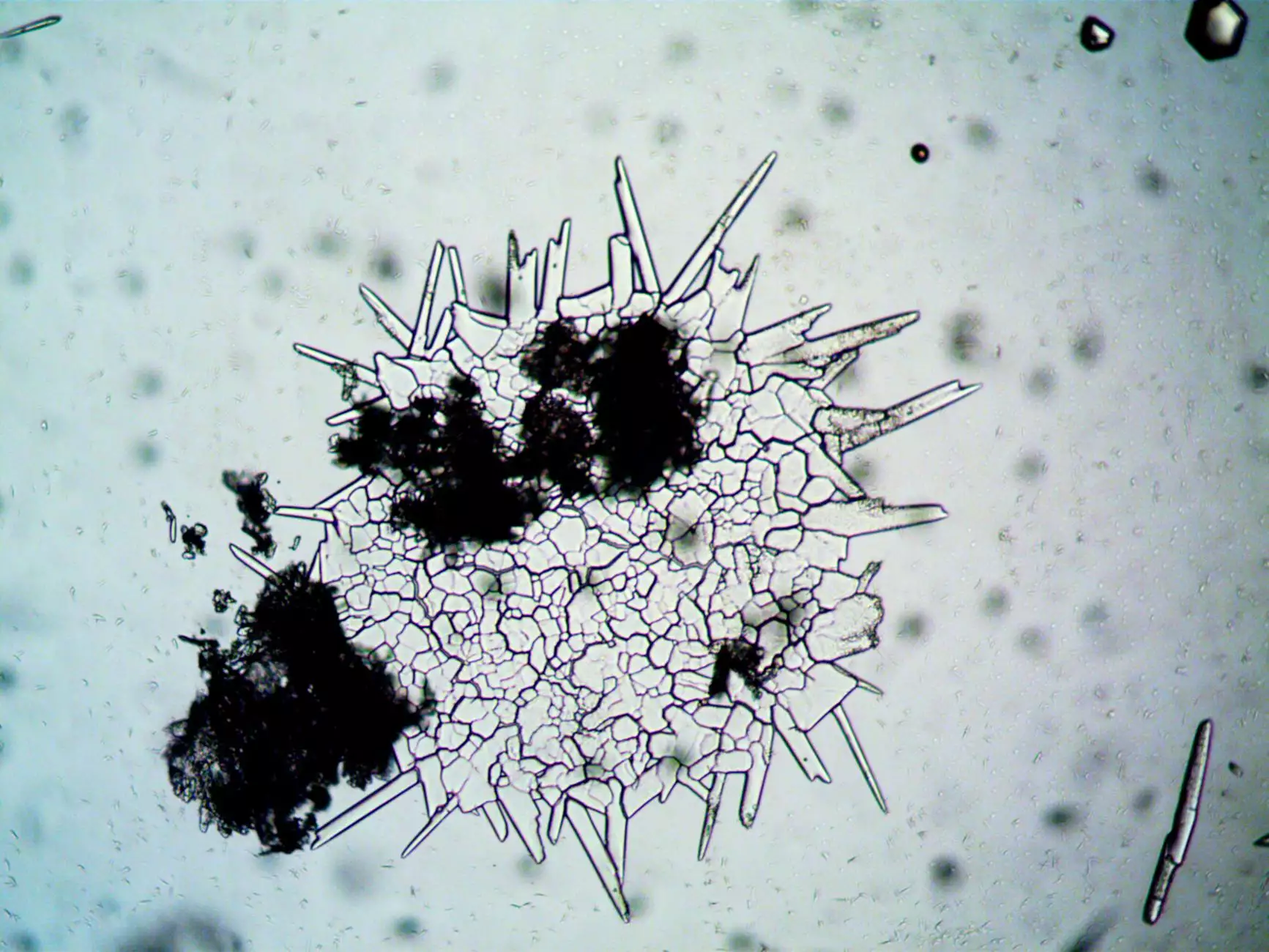

Quality is at the heart of what we do. We adhere to stringent quality control processes throughout the manufacturing cycle to ensure that every product meets the highest industry standards. Our quality assurance measures include:

- Regular inspections and testing of materials and finished products.

- Compliance with industry certifications and standards.

- Continuous improvement practices to enhance our quality systems.

Injection Moulding Applications Across Industries

The versatility of injection moulding means that it is employed across a wide range of industries, each with its specific requirements and challenges. Some of the primary sectors benefiting from injection moulding include:

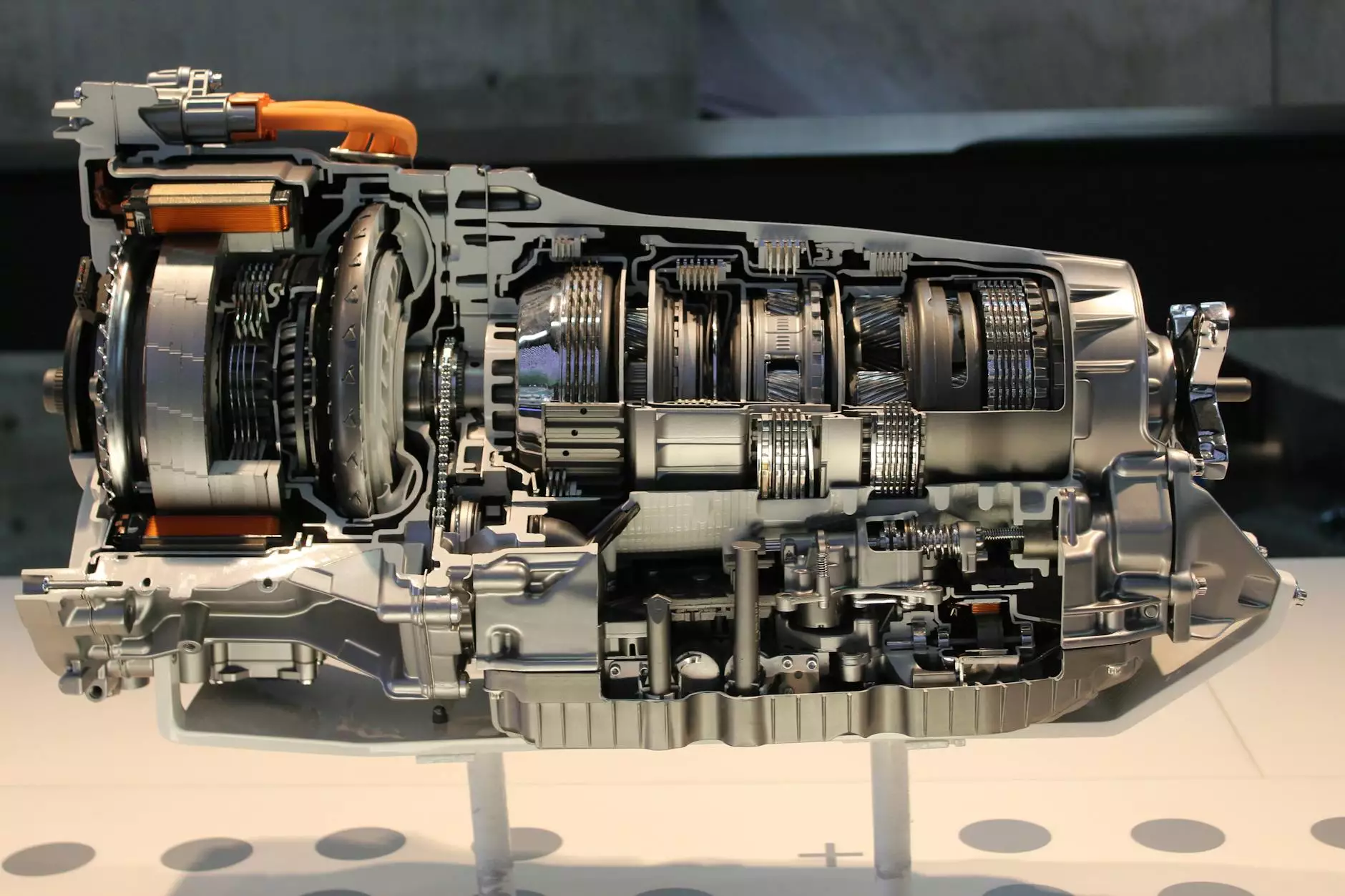

1. Automotive Industry

The automotive sector is one of the largest consumers of injection-moulded parts. From dashboard components to intricate engine parts, injection moulding allows manufacturers to produce durable and lightweight pieces that enhance vehicle performance.

2. Consumer Goods

Injection moulding is widely used in the production of household items, toys, and electronics. The ability to mold high-volume parts cost-effectively makes it ideal for creating everything from kitchen utensils to complex electronic housings.

3. Medical Devices

In the medical field, precision and quality are paramount. Injection moulding manufacturers create components for medical devices, ensuring compliance with strict regulatory standards. This can include anything from surgical instruments to disposable syringe systems.

4. Packaging Industry

Packaging solutions often require both durability and aesthetic appeal. Injection moulding enables the production of high-quality packaging products, including containers and caps that are essential for protecting products and enhancing shelf appeal.

Environmentally Friendly Practices in Injection Moulding

As an injection moulding manufacturer, we are conscious of our environmental impact. Sustainability is a critical consideration in our production processes, and we strive to reduce waste and energy consumption. Our initiatives include:

- Recycling Programs: We prioritize using recycled materials in our injection moulding processes. This not only reduces waste but also conserves natural resources.

- Energy Efficiency: Our operations utilize energy-efficient machines that reduce our carbon footprint while maintaining high productivity levels.

- Responsible Waste Management: We adhere to best practices in waste management, ensuring that any scrap material is properly recycled or disposed of.

Future Trends in Injection Moulding

The injection moulding industry is continually evolving, driven by advancements in technology and changing market demands. Some of the trends shaping the future of injection moulding include:

1. Automation and Industry 4.0

Automation is becoming increasingly significant in manufacturing, and injection moulding is no exception. With the integration of IoT and AI technologies, manufacturers can enhance efficiency and reduce operational costs.

2. Use of Advanced Materials

Scientists and engineers are developing new materials with enhanced properties, such as bio-degradable plastics and composites. These materials not only improve the performance of end products but also contribute to sustainability.

3. Customization and On-demand Manufacturing

As consumer preferences shift towards personalized products, injection moulding manufacturers are increasingly adopting on-demand manufacturing techniques. This allows for short production runs and customization without significant cost penalties.

Choosing the Right Injection Moulding Manufacturer

Selecting the right injection moulding manufacturer is crucial for your business success. Here are some tips to consider when making your choice:

- Experience and Expertise: Look for manufacturers with a proven track record and expertise in your specific industry.

- Technological Capability: Ensure that the manufacturer employs the latest technology and machinery to deliver high-quality products.

- Customer Support: Strong communication and support throughout the project lifecycle are essential for a successful partnership.

- Cost and Value: Evaluate the pricing structures. While cost is an important factor, consider the value you receive in terms of quality and service.

Conclusion

As a leading injection moulding manufacturer, DeepMould.net is dedicated to providing comprehensive solutions that not only meet but exceed the needs of our clients. Our focus on quality, innovation, and sustainability positions us at the forefront of the manufacturing industry. By choosing us, you are partnering with a company that values your success and is committed to delivering superior products and services.

Explore the endless possibilities that injection moulding can bring to your business. Contact us today to learn more about how we can help you achieve your manufacturing goals!