The Power of Base Oil Production in the Automotive, Auto Parts & Supplies, and Oil Change Stations Industry

The automotive, auto parts & supplies, and oil change stations industry heavily relies on base oil production for its lubricant needs. Base oil, also known as base stock, serves as a crucial component in manufacturing high-quality lubricants that facilitate smooth operation, reduce friction, and extend the lifespan of machinery and engines.

The Benefits of Base Oil Production

Base oil is derived from crude oil through an extensive refining process, which removes impurities and enhances its lubricating properties. The result is a versatile and reliable lubricant that offers several benefits:

- Enhanced Performance: Base oil production ensures lubricants can withstand extreme temperatures, heavy loads, and harsh operating conditions, providing superior performance and protection for automotive components and machinery.

- Reduced Friction and Wear: Lubricants formulated with high-quality base oils minimize friction and wear between moving parts, reducing the risk of component failure and extending equipment longevity.

- Improved Fuel Efficiency: Advanced base oil production techniques contribute to the creation of efficient lubricants that promote fuel economy, helping businesses and individuals save on fuel costs.

- Environmental Sustainability: Base oil production has evolved to produce eco-friendly lubricants with reduced emissions and biodegradable properties, supporting environmental sustainability initiatives in the industry.

- Compatibility: Base oil production techniques ensure compatibility with various additives, allowing lubricant manufacturers to tailor formulations specific to different applications and requirements.

Applications of Base Oil in the Automotive, Auto Parts & Supplies, and Oil Change Stations Industry

Base oil production plays a crucial role across multiple sectors within the automotive, auto parts & supplies, and oil change stations industry. Here are some prominent applications:

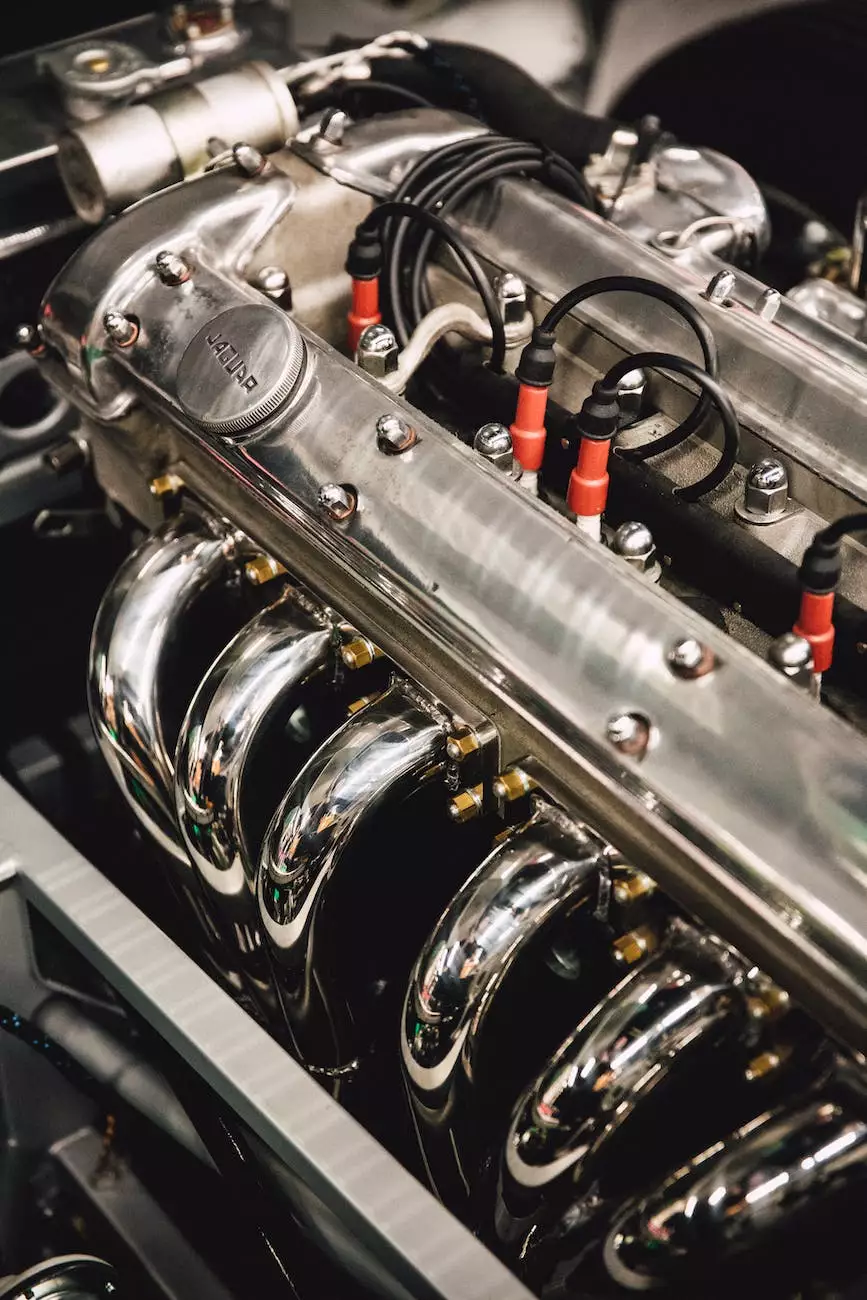

Engine Oils

Engine oils are essential for maintaining optimal performance and protecting the engine components of vehicles. Base oil serves as the primary ingredient in engine oil formulations due to its exceptional lubricating properties and ability to withstand high temperatures.

Transmission Fluids

Transmission fluids are necessary for smooth gear shifting, cooling, and protection of transmission systems. Base oil, along with selective additives, provides the necessary viscosity and lubrication to optimize transmission performance and prevent damage.

Hydraulic Fluids

Hydraulic fluids are vital for transmitting power within hydraulic systems, enabling precise control and smooth operation. Base oil, when combined with specialized additives, ensures optimal lubrication, corrosion protection, and heat transfer capabilities in hydraulic applications.

Gear Oils

Gear oils are designed to protect gears and bearings from wear and extreme pressures. Base oil's robust film strength, coupled with appropriate additives, helps prevent metal-to-metal contact, reducing friction, noise, and the risk of component failure.

Metalworking Fluids

Metalworking fluids, including cutting oils and coolants, are extensively used in manufacturing processes to improve machining performance and tool life. Base oil, combined with specialized additives, functions as a coolant, lubricant, and chip evacuator, enhancing efficiency and reducing costs.

Evolving Technologies in Base Oil Production

Base oil production continues to evolve to meet the demanding requirements of the automotive, auto parts & supplies, and oil change stations industry. Technological advancements have led to the development of higher-quality base oils with improved performance characteristics:

Group II and Group III Base Oils

Group II and Group III base oils are two popular categories of base oils known for their enhanced purity, higher viscosity index, and better oxidation resistance compared to conventional Group I base oils. These advanced base oils provide improved friction control, wear protection, and thermal stability.

Synthetic Base Oils

Synthetic base oils, such as polyalphaolefins (PAOs) and esters, are chemically engineered to offer exceptional lubrication properties. These base oils provide excellent thermal stability, oxidation resistance, and low-temperature fluidity, making them ideal for extreme operating conditions.

Hydrocracking and Hydroisomerization

Hydrocracking and hydroisomerization processes play a significant role in base oil production. These technologies help refine crude oil to produce base oils with improved viscosity index, lower sulfur content, and better stability, resulting in high-performance lubricants.

In conclusion, base oil production occupies a central position in the automotive, auto parts & supplies, and oil change stations industry. By leveraging the benefits of base oil - enhanced performance, reduced friction and wear, improved fuel efficiency, environmental sustainability, and compatibility - businesses can optimize their operations, protect critical components, and achieve higher levels of customer satisfaction. As the base oil production technologies continue to advance, lubricant manufacturers and service providers can offer superior products that meet the evolving needs of the industry, contributing to its growth and success.